Forrestfield Airport Line

The multi-award-winning project in Perth

The Project

The multi-award-winning Airport Line, formerly known as the Forrestfield-Airport Link, is a major piece of Perth’s infrastructure network as the Western Australian state capital invests in public transport through its METRONET programme to prepare for a projected doubling of its population to 3.5 million by 2050.

The public opening of the rail line in October 2022 was declared a “historic” event by Australian Prime Minister Anthony Albanese, who attended the ribbon-cutting ceremony to highlight the project’s importance to the city. Commissioned by the Public Transport Authority, it was one of the biggest and most complex public transport infrastructure projects undertaken in the state.

The line connects the eastern suburbs with the central business district via the international airport. It runs between the existing Midland Line near Bayswater Station in the centre and the eastern district of Forrestfield. It is 8.5 kilometres long, eight of which are underground. It has three stations: High Wycombe at its easternmost, Airport Central at the Perth Airport, and Redcliffe where the line connects with Midland.

Webuild built the line with joint-venture partner NRW Pty Ltd. With an 80% stake, Webuild led the project, which included twin-bored tunnels, three emergency egress shafts and parking spaces to serve the stations.

Redcliff_DSF6627

People behind the Forrestfield-Airport Link Project

Forrestfield-Airport Link, Perth - Webuild Project

Forrestfield-Airport Link – Project Completion

Forrestfield Airport-Link, Perth - Supply Chain

Forrestfield-Airport Link Info-Graphic

The new metro rail lines

The project will allow residents in the eastern suburbs of Perth to travel 20 minutes to the city centre

+ + +

daily passenger trips

+ + +

trips capacity by 2031

+ + +

cars off the road, reducing road traffic

The Benefits of the Project

The ForrestfiledAirport Line more than halves travel times to the central business district for commuters, going from 45 minutes by car to 20 minutes by train. It provides 20,000 passenger trips a day, and is expected to have a capacity of up to 29,000 trips by 2031. Its trains operate every 12 minutes at peak times, every 15 minutes during off-peak times in the day and every 30 minutes at night.

The line is expected to have led to a reduction of an estimated 15,000 cars from city streets, contributing to an easing of traffic and the avoidance of 2,000 tons of CO2 emissions per year.

It has also been a catalyst for residential and commercial development in the precincts around the three stations, creating opportunities for local businesses and communities.

The Forrestfield Airport Link Project Details

Each tunnel is 8 kilometres long, with an internal diameter of 6.17 metres and an excavation diameter of 7 metres.

The two tunnel-boring machines (TBMs) faced the challenge of advancing through varying geology with a presence of water. They also excavated below operating rail lines, the airport’s runways, and the Swan River, where they reached a maximum depth of 26 metres below ground.

The Forrestfield Airport Link Project: Innovation and Technologies

Webuild brought a number of innovative solutions to the project to overcome the challenges posed by the route chosen to excavate the twin tunnels. It was also mindful of being as sustainable as possible in the construction of the line.

The TBMs reused the water they needed to function by having a plant use a filter press and centrifuge to process the slurry generated by the excavating, separating the spoil from the water. The plant would then send the water back to the TBMs. In the end, this method saved 2740 megalitres of water, the equivalent of more than 1000 Olympic-sized swimming pools.

As the TBMs worked under the Perth Airport, Webuild had installed more than 10,000 sensors to monitor the operating runway and ensure no ground movement occurred..

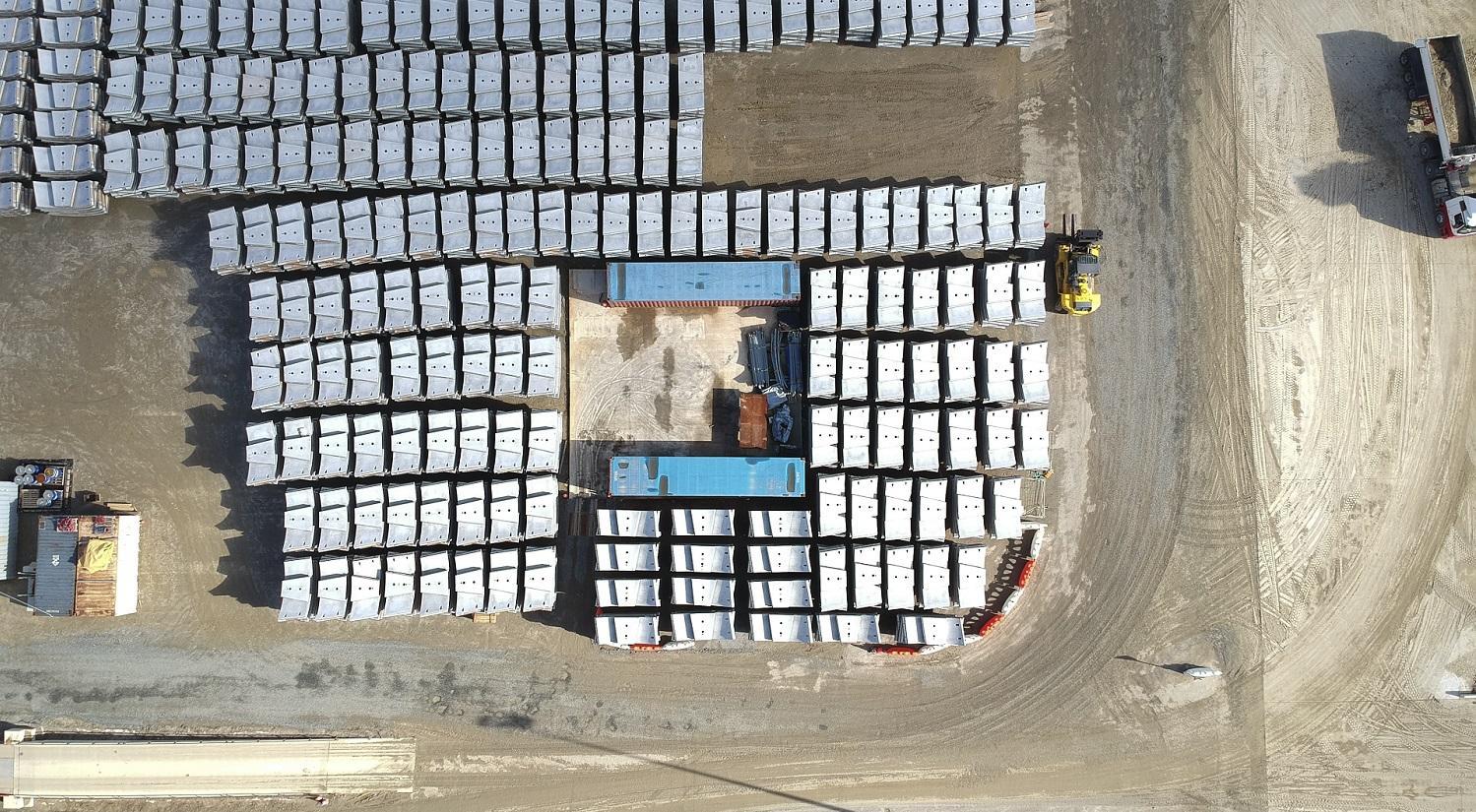

Another area of focus was the concrete. Webuild worked with a local supplier to develop two sustainable concrete blends, one of which for the production of the segments that came to line the tunnel walls. Known as Triple Blend 60MPa Concrete, it was a low-cement concrete blend containing 65 percent supplementary cementitious materials, such as ground-granulated blast-furnace slag, which is itself a recycled material. This blend had only 195 kilograms of cement per cubic metre of concrete, compared with more than 550 kilograms in typical 60Mpa Concrete. By using this blend rather than the concrete made with Portland Cement – which requires a lot of energy to produce – a total of 21,848 tonnes of CO2 emissions were avoided in the production of the 54,000 tunnel segments that line the walls of a combined total of 15 kilometres of tunnels.

For the production of track slabs on which the rails are positioned along the line, Webuild resorted to concrete reinforced with macro synthetic fibres rather than steel. This avoided the use of 6.96 metre-kilograms of steel, preventing about 13,224 tonnes of CO2 being emitted during production.

At High Wycombe Station, Webuild had the largest solar panel system to be installed for a state government department in Western Australia. The 275-kilowatt system is sufficient to meet the average summertime daylight electricity demand of all three stations.

Community

A firm commitment to social procurement policies saw more than 55 percent of the people working on the project aged under 40 years. And more than 25 nationalities were represented on the work sites.

The percentage of total hours of work on the project undertaken by Indigenous Australians was 2.57 percent in October 2020, higher than the assigned 2.0 percent target.

Webuild Awards

As it was under construction, the project received in 2018 an “excellent” rating from the Infrastructure Sustainability Council of Australia (ISCA) for its commitment to delivering an innovative and sustainable transport solution to Perth.

In 2019, Webuild and NRW received the Award for Excellence in the Technology and Innovation Category from the Western Australia Branch of the Concrete Institute of Australia for the design and manufacture of the precast concrete segments lining the tunnel walls. They were commended for the quality, durability and sustainability of the concrete used.

In 2023, the Airport Central Station received the Award for Public Architecture (Chapter Western Australia) in recognition of the excellence in design and architecture. The award was promoted by the Australian Institute of Architects.